News

A Significant Step Toward Greater Clarity in Polymorph Control for Innovative Drugs

28 Jan 2026

Solid Form Screening

Our solid form screening technology applies to polymorph screening, salt screening and cocrystal screening. Our screening technology is to design various crystallization conditions according to the physicochemical properties of the target compound and factors affecting drug crystallization, to screen and discover the most comprehensive solid form for subsequent evaluation and development. Our proprietary solid form screening technology has been applied to over 1,500 different drug molecules and proven to be efficient and effective in screening and identifying the most optimal solid form for development.

Solid Form Screening

Our solid form screening technology applies to polymorph screening, salt screening and cocrystal screening. Our screening technology is to design various crystallization conditions according to the physicochemical properties of the target compound and factors affecting drug crystallization, to screen and discover the most comprehensive solid form for subsequent evaluation and development. Our proprietary solid form screening technology has been applied to over 1,500 different drug molecules and proven to be efficient and effective in screening and identifying the most optimal solid form for development.

Solid Form Developability Evaluation

Solid form developability evaluation technology is to evaluate the developability of crystal forms, including polymorphs, salts and cocrystals obtained in the solid form screening experiments and analyze potential risks and challenges of development. Through years of technical accumulation, Crystal Pharmatech has formed a complete evaluation system for solid form developability.

Solid Form Developability Evaluation

Solid form developability evaluation technology is to evaluate the developability of crystal forms, including polymorphs, salts and cocrystals obtained in the solid form screening experiments and analyze potential risks and challenges of development. Through years of technical accumulation, Crystal Pharmatech has formed a complete evaluation system for solid form developability.

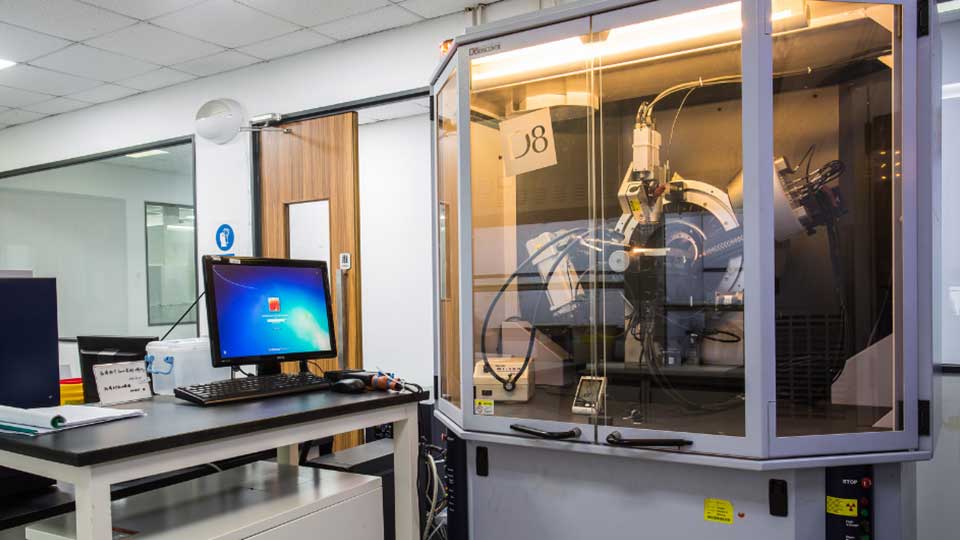

Absolute Structure Determination

Single crystal growth and structure determination technology are the main methods to determine the absolute configuration of drug molecules and identify the crystal forms absolutely. The single crystal culture and analysis technology firstly obtain high-quality crystals through a variety of experimental single crystal growth methods. The main single crystal growth methods include slow evaporation, gas-liquid infiltration, slow cooling and liquid surface diffusion.

Absolute Structure Determination

Single crystal growth and structure determination technology are the main methods to determine the absolute configuration of drug molecules and identify the crystal forms absolutely. The single crystal culture and analysis technology firstly obtain high-quality crystals through a variety of experimental single crystal growth methods. The main single crystal growth methods include slow evaporation, gas-liquid infiltration, slow cooling and liquid surface diffusion.

Crystallization Process Development

On the basis of in-depth research on the properties of the crystal form itself and the transformation relationship between crystal forms, Crystal Pharmatech's crystallization process development technology realizes the selection and control of the crystallization system, crystallization conditions and post-processing conditions, so as to obtain the target crystal form at the same time taking into account the API particle properties, yield and cost, etc.

Crystallization Process Development

On the basis of in-depth research on the properties of the crystal form itself and the transformation relationship between crystal forms, Crystal Pharmatech's crystallization process development technology realizes the selection and control of the crystallization system, crystallization conditions and post-processing conditions, so as to obtain the target crystal form at the same time taking into account the API particle properties, yield and cost, etc.

Improving the Manufacture of mRNA Biologics

Improving the Manufacture of mRNA Biologics

Solid Form Landscape to Formulation Strategy: The Role of Computational Screening and Risk Assessment

Unexpected polymorphs can upend formulation by shifting solubility, stability, and manufacturability.This webinar shows how in silico crystal structure prediction (CSP), paired with competing-form ris...

Solid Form Landscape to Formulation Strategy: The Role of Computational Screening and Risk Assessment

Unexpected polymorphs can upend formulation by shifting solubility, stability, and manufacturability.This webinar shows how in silico crystal structure prediction (CSP), paired with competing-form ris...

Determination and Control of Crystal Form in ASD Formulations: A Case Study on Everolimus Tablets

Amorphous solid dispersion (ASD) is a formulation strategy in which a drug is molecularly dispersed in a suitable polymer matrix, forming an amorphous solid solution or suspension that can markedly en...

Determination and Control of Crystal Form in ASD Formulations: A Case Study on Everolimus Tablets

Amorphous solid dispersion (ASD) is a formulation strategy in which a drug is molecularly dispersed in a suitable polymer matrix, forming an amorphous solid solution or suspension that can markedly en...

_.webp) A Significant Step Toward Greater Clarity in Polymorph Control for Innovative Drugs

Suzhou, China – January 28, 2026 – A regulatory authority has released the world's first guideline dedicated specifically to polymorph research for innovative chemical drugs, providing a structu...

A Significant Step Toward Greater Clarity in Polymorph Control for Innovative Drugs

Suzhou, China – January 28, 2026 – A regulatory authority has released the world's first guideline dedicated specifically to polymorph research for innovative chemical drugs, providing a structu...

Crystal Pharmatech Viewpoint: Analysis of Crystal Form Patent Layouts for Small Molecule New Drugs Approved by the FDA in 2025

1. Overview of FDA New Drug Approvals in 2025In 2025, the U.S. Food and Drug Administration (FDA) approved a total of 46 new drugs [1], including 34 new molecular entities (NMEs). Among these, 30 are ...

Crystal Pharmatech Viewpoint: Analysis of Crystal Form Patent Layouts for Small Molecule New Drugs Approved by the FDA in 2025

1. Overview of FDA New Drug Approvals in 2025In 2025, the U.S. Food and Drug Administration (FDA) approved a total of 46 new drugs [1], including 34 new molecular entities (NMEs). Among these, 30 are ...

San Diego Biotech Reception: Cocktails & Conversations with Crystal Pharmatech

An Evening of Unscripted Connection, we're hosting a relaxed evening at Gravity Heights designed specifically for the San Diego Biotech and Pharma R&D community. Whether you want to dive deep ...

San Diego Biotech Reception: Cocktails & Conversations with Crystal Pharmatech

An Evening of Unscripted Connection, we're hosting a relaxed evening at Gravity Heights designed specifically for the San Diego Biotech and Pharma R&D community. Whether you want to dive deep ...

Predicting Physical Stability of Amorphous Solid Dispersions (ASD)

01 IntroductionAt present, new drug compounds are becoming increasingly complex, and the proportion of poorly water-soluble drugs continues to rise. It is estimated that 40% of marketed oral drugs and...

Predicting Physical Stability of Amorphous Solid Dispersions (ASD)

01 IntroductionAt present, new drug compounds are becoming increasingly complex, and the proportion of poorly water-soluble drugs continues to rise. It is estimated that 40% of marketed oral drugs and...

Subscribe to be the first to get the updates!